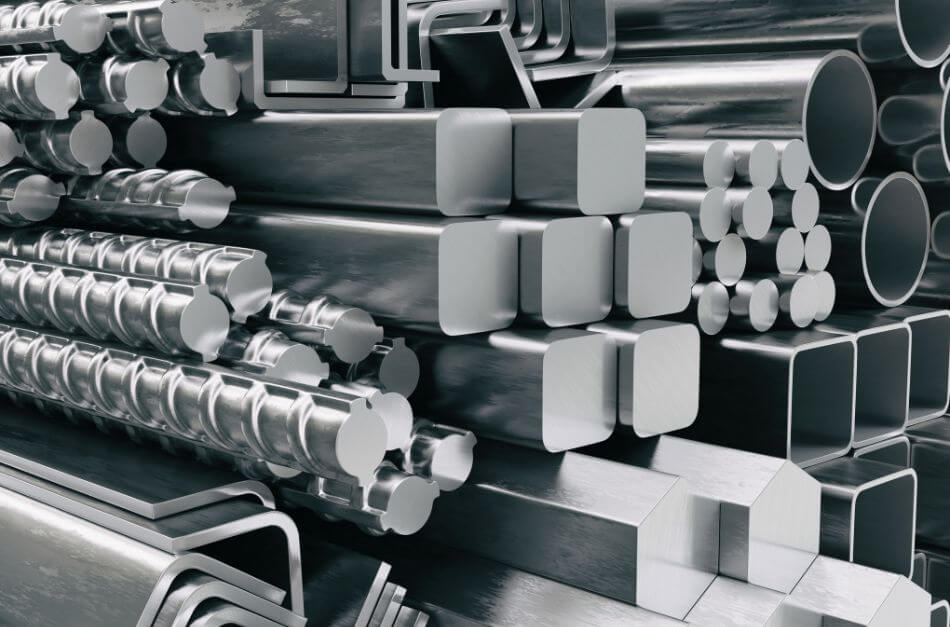

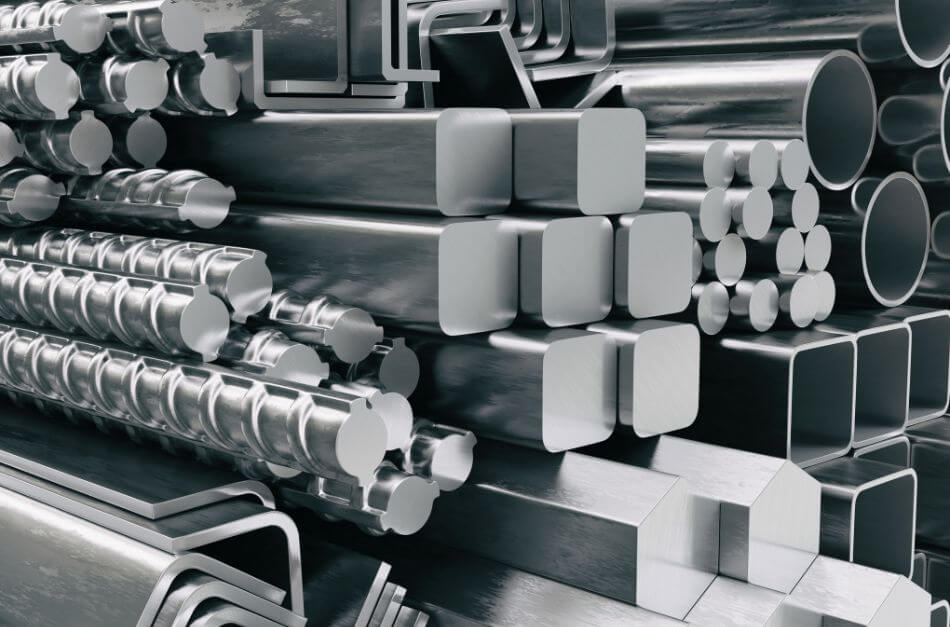

Understanding the Four Types of Steel

Steel is a cornerstone material in the vast world of metallurgy, boasting an unparalleled blend of durability, versatility, and affordability. But not all steels are created equal. There are four primary types: carbon steel, alloy steel, stainless steel, and tool steel. Each type possesses unique properties and applications, making it crucial for industry professionals, hobbyists, and consumers to distinguish among them.

Carbon Steel

Carbon steel, as the name suggests, primarily contains iron and carbon, with a carbon content of up to 2.5%. It is divided into low, medium, and high-carbon steels. The greater carbon content enhances hardness and strength but decreases ductility.

How to Identify:

This type of steel is magnetic and can rust easily if not protected. Its surface is dull and matte, with a rough texture. A spark test will produce longer and thinner sparks, with fewer branches, indicative of its carbon content. Also, when applying a file test, carbon steel shows a faster material removal rate than harder steel, reflecting its softer nature.

Applications in Hand and Power Tools:

Carbon steel is widely used to manufacture hand tools such as hammers, screwdrivers, and wrenches. Low-carbon steel, being more ductile, is often used in parts where a bit of flexibility is beneficial, such as tool handles.

With its balanced strength and ductility, medium carbon steel is preferred for striking tools like hammers, which can absorb impact without deforming or breaking. High carbon steel, known for its hardness, is used in cutting tools and files where sharp edges and durability are crucial.

Alloy Steel

Alloy steel contains various elements, such as chromium, nickel, manganese, and vanadium, in varying proportions. These enhance specific properties like strength, hardness, corrosion resistance, and toughness to meet a wide range of applications.

How to Identify:

Depending on their composition, alloy steels can be magnetic. They usually have a brighter finish than carbon steels and respond differently to heat treatment. This steel often results in varying levels of hardness across a single piece. Spark tests show more branched sparks, reflecting the diversity of elements present.

Applications in Hand and Power Tools:

The enhanced strength and resistance to wear and fatigue make alloy steel ideal for components in power tools that undergo high stress and need to resist deformation under load. For instance, gears, spindles, and shafts in electric drills and saws are often made of alloy steel. Added elements like chromium and nickel offer improved toughness and corrosion resistance, essential for tools exposed to harsh conditions and heavy use.

Stainless Steel

Stainless steel is best known for its corrosion resistance, which is achieved by adding at least 10.5% chromium. Different types of stainless steel are ferritic, austenitic, and martensitic.

How to Identify:

Stainless steel is non-magnetic (with the exception of some martensitic and ferritic grades) and has a bright, shiny finish. It does not rust easily, making it ideal for culinary, medical, and marine applications. Due to its high chromium content, a spark test typically yields few sparks.

Applications in Hand and Power Tools:

Stainless steel's resistance to corrosion and easy cleaning make it suitable for tools used in medical, food, and cleanroom environments, where hygiene is paramount. In power tools, stainless steel may be used for exterior components that come into contact with corrosive materials or need to maintain a clean surface to prevent contamination. It's also used in specialty hand tools like pliers and scissors used in marine applications, where resistance to saltwater corrosion is crucial.

Tool Steel

Tool steel is geared for tool manufacturing. It contains elements such as tungsten, molybdenum, cobalt, and vanadium, which have a high hardness and resistance to wear and temperature. Based on the preferred cooling medium, tool steel is categorized into various grades, such as water-hardening, air-hardening, and oil-hardening types.

How to Identify:

Tool steel can be very hard and resistant to scratching. It is magnetic and often has a distinctive, somewhat polished look. Spark tests reveal sparks with pronounced bursting patterns, indicative of the various alloying elements designed to enhance performance. A hardness test, such as using a file or a diamond indent, will further confirm its high resistance to deformation.

Applications in Hand and Power Tools:

Tool steel's hardness and resistance to abrasion and temperature make it the go-to material for cutting edges and precision parts. Drill bits saw blades, and cutting tools are often made from various grades of tool steel.

For hand tools requiring impact resistance, such as chisels and punches, certain grades of tool steel that offer both hardness and toughness are preferred to withstand repeated use without damage.

Connecting Material to Function

The selection of steel type for components in hand and power tools is a critical decision that impacts the tool's performance, durability, and application suitability. By matching the steel's properties with the tool's requirements, manufacturers ensure that the final product can withstand the rigors of its intended use while providing the best possible performance.

Whether it's the toughness needed for a hammer, the precision required for a drill bit, or the corrosion resistance crucial for marine pliers, the choice of steel plays a pivotal role in the tool's effectiveness and longevity.

Understanding the nuances of the four types of steel is crucial for selecting the right material for your specific application. Whether you're crafting a kitchen knife, building a bridge, or manufacturing precision tools, recognizing the distinct characteristics of carbon, alloy, stainless, and tool steels can guide you to the best choice for durability, performance, and cost-efficiency.